who we are

About Us

Our Story

Phoenix Park Gas Processors Limited is located on the Point Lisas Industrial Estate, the heart of Trinidad and Tobago’s petrochemical sector.

Who we are

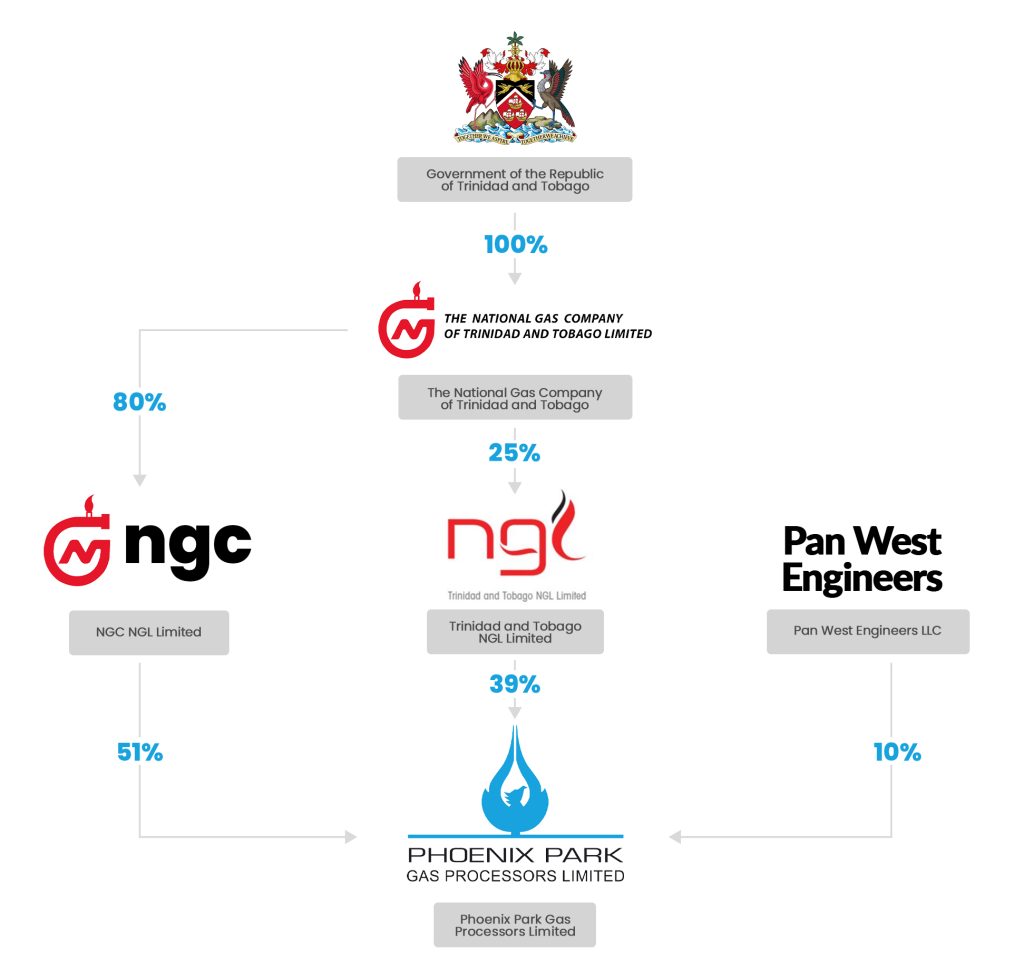

Phoenix Park Gas Processors Limited is a Trinidad and Tobago company, which was formed in May 1989. It is owned by NGC NGL Company Limited (51%), Trinidad and Tobago NGL Limited (39%) and Pan West Engineers & Constructors LLC (10%)

Our solutions

Processing

Fractionating

Marketing

Sourcing

Trading and Transporting

What we do

Phoenix Park Gas Processors Limited (PPGPL) is a leading natural gas processing, fractionation, and NGL marketing company based in Trinidad and Tobago. Established in 1991, PPGPL plays a pivotal role in the region’s energy sector by processing natural gas supplied by the National Gas Company of Trinidad and Tobago (NGC). The main natural gas stream is processed and separated into lighter hydrocarbons (methane and ethane) and natural gas liquids (NGLs). The lighter hydrocarbons are redelivered to NGC for distribution to various downstream industries on the island, including ammonia, methanol, and power generation plants. The NGLs obtained from gas processing on the facility combined with additional volumes from Atlantic LNG facility are then fractionated into component streams of propane, butane, and natural gasoline. These products are kept in storage tanks and marketed to customers via truck tanker wagon or seafaring vessels.

Ownership structure

Phoenix Park Gas Processors Limited is a Trinidad and Tobago company, which was formed in May 1989. It is owned by NGC NGL Company Limited (51%), Trinidad and Tobago NGL Limited (39%) and Pan West Engineers & Constructors LLC (10%)

Our Growth

PPGPL's Growth

PPGPL has undertaken many capital investments to expand its initial facility that was commissioned in June 1991. The following growth projects have been implemented:

First Acquisition

On February 1, 2020, PPGPL through its wholly owned US subsidiary, Phoenix Park Energy Marketing LLC, acquired the NGL marketing assets of Twin Eagle Liquids Marketing LLC of Houston Texas, USA, which is engaged in the business of marketing, trading and transportation of natural gas liquids in Canada, USA and Mexico via rail.

Second Acquisition

Phoenix Park Hull Terminal in Hull Texas formally Keyera Energy Inc. NGL’s Terminal

Third Acquisition

Phoenix Park Rush City Terminal in Minnesota formally Interstate Fuel and Energy’s propane terminal.

Storage Expansion Project

This expansion increased natural gasoline storage from 350,000 barrels to 600,000 barrels; and total storage from 1,000,000 barrels to 1,250,000 barrels.

Phase 3 Expansion

This expansion was completed in August 2009 and increased PPGPL’s gas processing capability from 1,350 mmcfd to 1,950 mmcfd

Iso-Butane Facility

This project created the opportunity for PPGPL to split its mixed butane product into normal and iso-butane; the latter being supplied to Petrotrin under a 10-year sale agreement

The Fractionation Expansion 3 Project

This expansion involved the construction of a stand-alone fractionation facility that resulted in an increase in the company’s fractionation capacity from 46,000 BPD to 70,000 BPD. This increase catered for the fractionation of the natural gas liquids from the Phase 3 facility and ALNG T4

The Fractionation, Storage and Expansion 2 Project

This increased fractionation capacity from 33,500bpd to 46,000bpd and natural gas liquid storage capacity from 750,000 barrels to 1,000,000 barrels; to receive and process the natural gas liquids from ALNG T2/3

The Phase 2 Expansion: This expansion

• increased PPGPL’s processing capacity from 750 MMCFD to 1,350 MMCFD • increased fractionation capacity from 13,500 to 33,500 barrels per day (bpd) • increased natural gas liquids storage capacity from 400,000 barrels to 750,000 barrels • expanded vessel handling capability from 22,000 cubic meters to 54,000 cubic meters by adding a second vessel loading port • increased vessel loading capability up to 10,000 barrels per hour • enabled the receipt of the natural gas liquids from ALNG T1 via the installation of an 8” natural gas liquids pipeline connecting ALNG to PPGPL

The Phase 1 Upgrade Project

This increased PPGPL’s gas processing capacity from 650 MMCFD to 750MMCFD

The Soldado Gas Gathering Project

This enabled PPGPL to process up to 42 MMCFD of associated gas that is gathered by Petrotrin thereby increasing the value of the resource

The Natural Gasoline Storage and Export Project

This enabled PPGPL to export natural gasoline and consequently obtain a higher netback value for that product